Zerstörungsfreie Analyse von Batterien und Brennstoffzellen

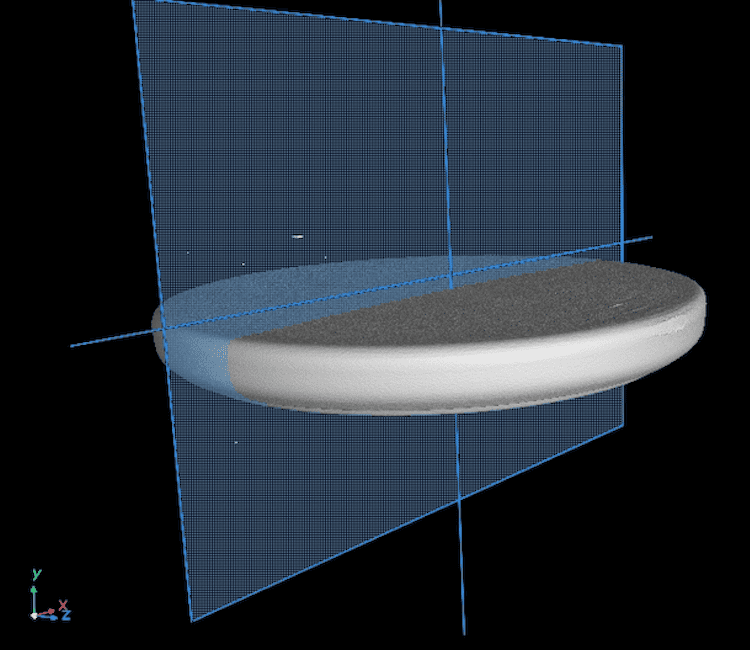

Mit der CT stellt das fem Kunden aus Industrie und Forschung eine Methode zur Verfügung, die eine zerstörungsfreie, dreidimensionale Erfassung und Charakterisierung beliebig komplexer Objekte aus allen Werkstoffklassen – Legierungen, Keramiken, Kunst- und Verbundwerkstoffe, biokompatible Werkstoffen sowie Baustoffe und Textilien – mit sämtlichen geometrischen und materialbezogenen Strukturen ermöglicht.

APPLICATION EXAMPLE: ELECTROCHEMICAL ENERGY SYSTEMS

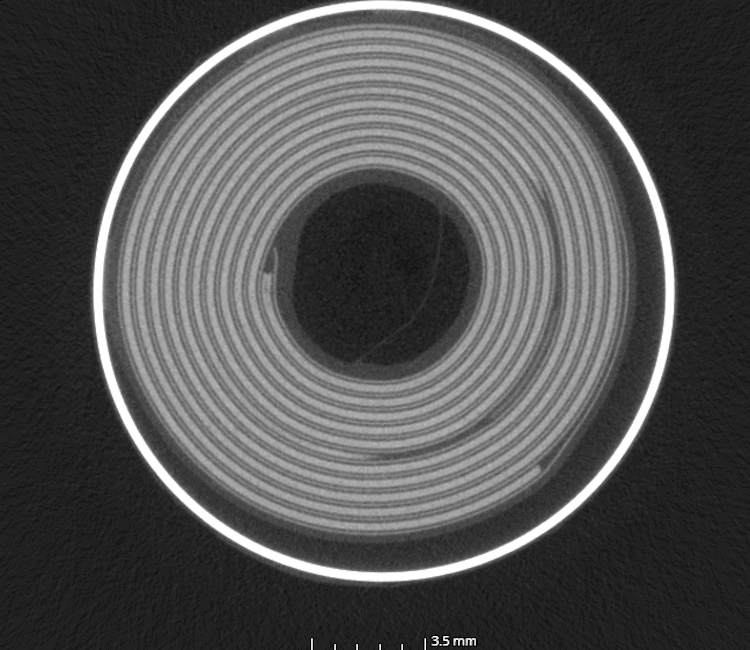

- Analysis of batteries (all cell formats, e.g. button cells, pouch cells, prismatic cells): Structure, contacting, deformations, impurities and causes of damage.

- Characterisation of fuel cells: Geometry and distance measurements, material and failure analysis

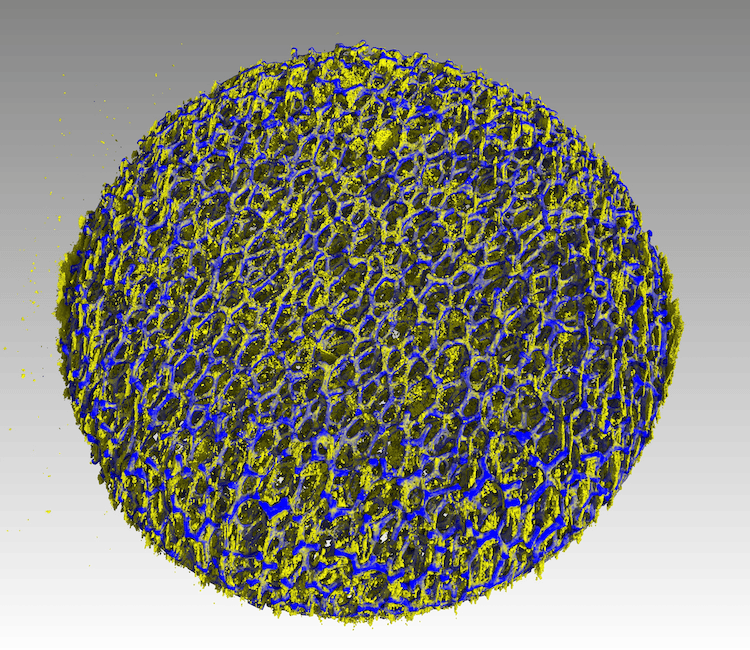

- Characterisation of components for batteries, fuel cells and electrolysis (e.g. electrodes, bipolar plates, gas diffusion layers)

Since 2010, we have been analysing a wide variety of objects, components and materials in our CT laboratory and dealing with a wide range of issues - quickly, precisely and reliably. Thanks to our extensive experience and our outstanding technology, we can provide you not only with measurement results, but also with real solutions to problems.

EXAMPLE PRICES FOR DIFFERENT MEASUREMENTS AND OBJECTS

INDUSTRIAL APPLICATION

- Non-destructive testing

- Damage Analysis

- Component testing, assembly inspection

- Quality management

- Metrology

- Dimensional control, target/actual comparison

- Shape detection, 3D wall thickness analysis

- Reverse Engineering

SCIENTIFIC APPLICATION

- Characterisation of different material classes

- Density or particle distribution

- Parameter optimisation using simulations

- Changes of state

- Computer-aided product development